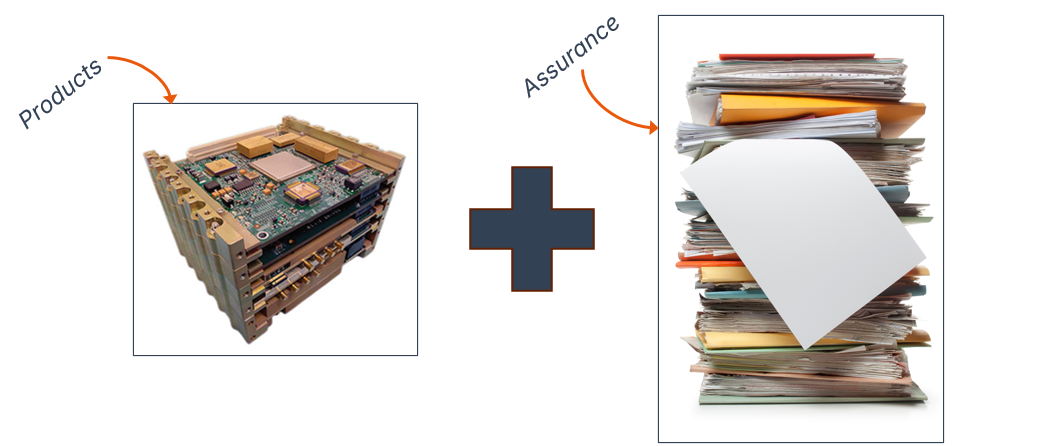

Market Expectations: Product Alone Is Not Enough

In the space industry, delivering hardware is only half the equation. Customers don’t just buy a subsystem or payload—they expect product assurance that proves reliability, safety, and mission readiness. This includes documented design reviews, analysis, testing, and traceability artifacts that often carry as much weight as the product itself. Without this assurance, even the most advanced hardware cannot be trusted to fly.

Meeting these expectations is essential for mission success, and it’s where Jemba9 delivers real value: pairing proven technology with the assurance class required to close a satellite integrator’s and mission operator’s business case: both government and commercial

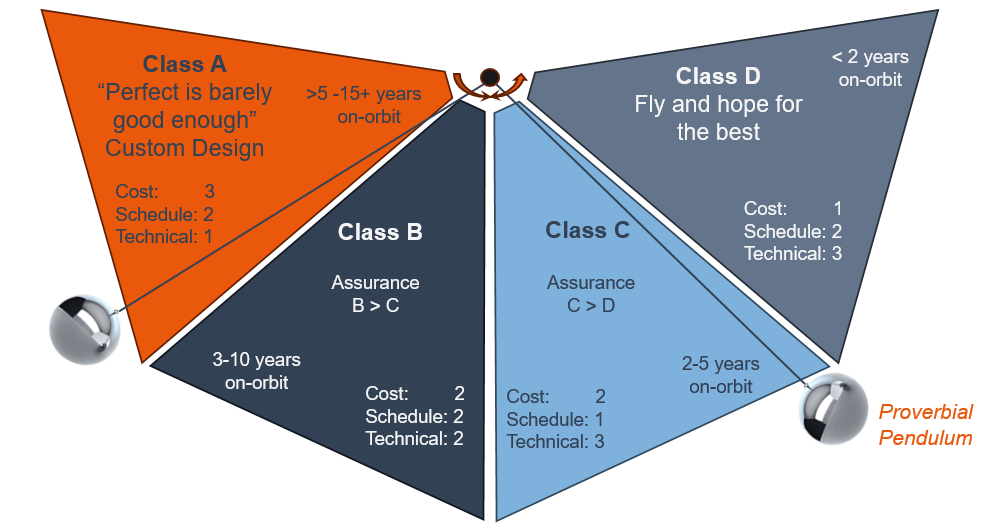

Range of Assurance

Assurance requirements for space solutions vary widely, from Class A missions where “perfect is barely good enough” to rapid development Class D programs that sometimes move so fast they end up “hoping for the best”. Navigating this spectrum is complex, and many suppliers struggle to deliver the right level of documentation, testing, and reliability for each mission type. Jemba9’s value lies in our expertise and AI-assisted tools that tailor assurance to the program’s needs, giving customers confidence they’ll meet mission expectations and close their business case without unnecessary cost or delay.

The challenge: Class A assurance is costly, and schedule takes too long. On the other hand, Class D isn’t sufficient to close the business case for a satellite operator.

The solution: Jemba9 achieves 5, 7 and 10 year on-orbit reliability with Class C and B assurance. This is possible by starting from an existing technology (far right of the range) and using our proprietary tools to adapt the design and move to the left into Class C and B.

A Full Picture: Production and Test

Designing for space is only half the battle. Once non-space technologies are adapted for space, their original production flows often fall short. That’s why Jemba9 not only perfects the design and assurance but also controls the production process while leveraging partner supply chains for maximum value and speed. As part of this strategy, we acquired a PCB assembly operation in April 2025, establishing J9CM. Through J9CM, we provide daily PCB assembly and test services that keep our production sharp and scalable while supporting customer programs. Explore our J9CM capabilities and contact us for a quote on your assembly and test needs.